ABOUT US

MRT is an Australian resources company with a unique business model based on the retreatment of mine tailings and other mineral processing wastes using its innovative, environmentally responsible and chemical-free physical mineral separation technology to produce valuable mineral concentrates for sale to downstream refineries.

THE MRT PROCESS

MRT has successfully developed a new, lost-cost, environmentally-benign, physical mineral separation technology that extracts base and precious metal sulphide minerals lost to froth flotation tailings and other mineral processing wastes. The unique advantages of the MRT Process are that it does not use any chemical reagents and it comprises a novel process flow sheet that utilises simple, ‘off-the-shelf’ plant proven to operate at scale and at low cost.

Development of the MRT Process followed strict QAQC protocols including engagement of independent experts to verify the efficacy of the process and veracity of test work results.

The most recent application of the MRT Process to nickel sulphide froth flotation tailings located at a Western Australian mine successfully yielded four nickel sulphide concentrate streams grading 8.2%, 5.2%, 2.9% and 1.0% nickel from a feed grade of 0.6% total (sulphide + silicate) nickel. Samples of the products generated are displayed below.

OUR DIFFERENCE

- MRT’s unique business strategy of recovering valuable minerals lost to mine tailings and other mineral processing wastes has very low energy requirements and therefore low operating costs and carbon dioxide (CO2) emissions per unit of metal produced. This is because the process feed is already mined, hauled to surface, crushed and pulverised.

- MRT is committed to sourcing 100% of its tailings excavation, conveying and mineral processing energy requirements from renewable sources at all its operations resulting in negligible CO2 output per unit of metal produced.

- The MRT Process is notable for its low capital and operating costs by virtue of its novel, chemical-free process flow sheet that utilises simple, existing, off-the-shelf mineral processing plant that already successfully operate at scale.

- Shareholders, consumers and governments around the world are increasingly concerned about the mineral resource industry’s environmental, social and corporate governance performance. MRT is one of only a handful of companies capable of satisfying the world’s rapidly growing demand for critical metals whilst meeting stakeholders’ ESG expectations.

OUR BUSINESS MODEL

MRT does not sell or licence its technology to others. Instead, its business model is to identify, acquire and develop wholly-owned surface mineral assets that are amenable to the application of its technology. MRT’s aim is to be the world’s leading supplier of ethical and environmentally responsible base and precious metals extracted from mineral processing waste.

MRT enables its partners and customers to meet their critical metal requirements in an ethical and environmentally responsible manner.

N Gellard, Executive Chairman, MRT

OUR COMMODITY FOCUS

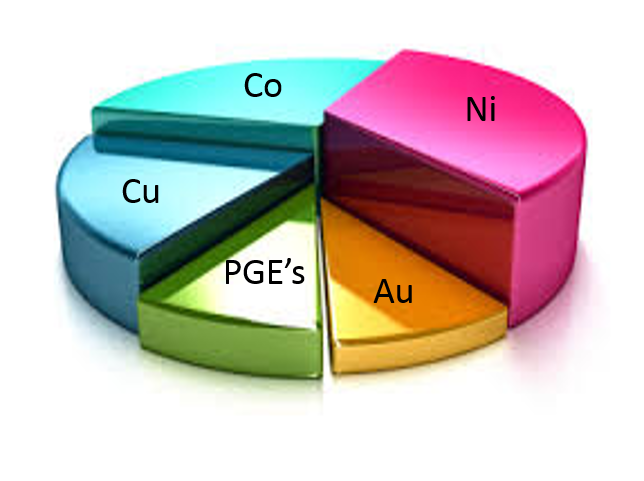

MRT’s Business is Multi Commodity & Global

MRT’s commodity focus is on the high-value base and precious metals required to meet emerging battery metal and Hydrogen Economy markets including nickel, cobalt, copper, vanadium and the platinum group elements (‘PGE’s’). However, diversification is also a key objective of the company as it provides a hedge against price cycle volatility. Consequently, MRT is also actively targeting gold and silver tailings reprocessing opportunities worldwide.